Our Story

THE BEGINNINGS

XTRACE SYSTEMS was born from the passion and expertise of two industry stalwarts, Daniel Simonavičius and Peter Kettell, boasting a combined experience of over five decades in Food Production Software. Their journey began out of a desire to break free from the limitations of outdated systems and instead create cutting-edge solutions. Tired of maintaining old software, they envisioned a brighter future and founded XTRACE SYSTEMS in February 2021. Their mission? To craft a vibrant, web-based solution using the latest technologies, catering to a loyal user base they had previously served. With xTrace.app, they reimagined and upgraded existing solutions, infusing them with innovation and a fresh, user-centric approach.

NEW HOPE

XTRACE SYSTEMS, a team of enthusiastic developers with reliable hardware partners, made an impressive entry into the market by upgrading R & J Seafoods, a prominent fish processor in Grimsby, with a hybrid software model that merges tradition with modern technology. Their major advancement was with John M Munro Ltd, a respected abattoir and catering butcher in Dingwall near Inverness, where they implemented the first fully new Xtrace.app system. Drawing on their global experience from Africa to North America, and in collaboration with their new hardware partner, Inspiron Systems, XTRACE developed an innovative meat factory production and traceability control system. This system, which integrates seamlessly with existing Abattoir and Sales Order Processing systems, establishes a new benchmark in food production management for efficiency and precision.

PIE IN THE SKY

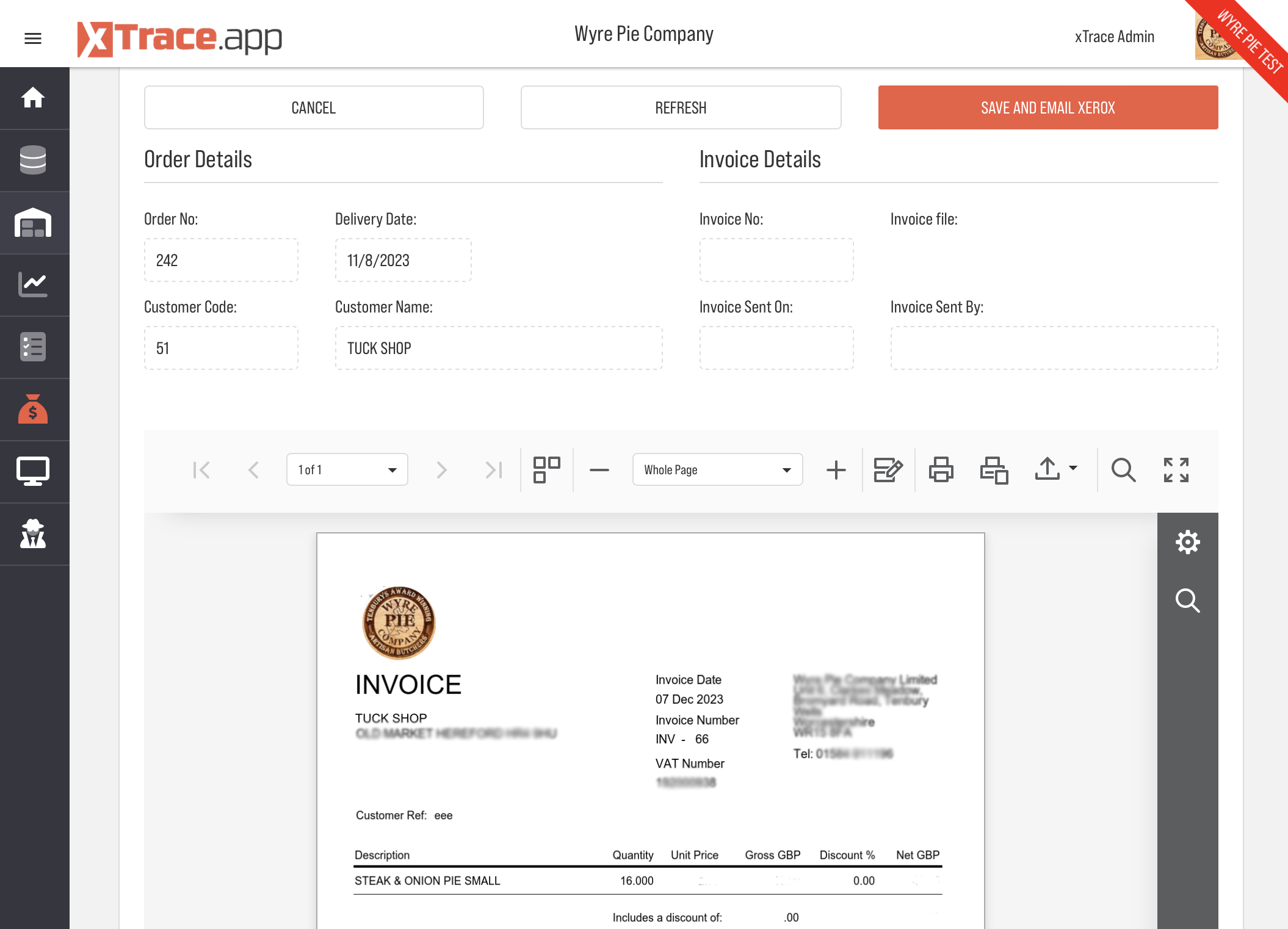

Xtrace.app built upon their initial success by providing a bespoke solution for the Wyre Pie Company, a distinguished butchery and bakery in Tenbury Wells, Worcestershire, known for their culinary excellence and accolades such as being finalists in the 2023 Eat Game award and receiving a 3-star rating in the Great Taste Awards. This solution transformed their operations, enhancing Purchase Order processing and Factory Intake, and establishing a comprehensive traceability chain from raw materials to finished products. Utilizing barcoding for unique traceability, Xtrace.app tracked each component through various stages including butchery, recipe formulation, cooking, packing, and integration with Sales Order Processing and Invoicing systems.

In the factory's retail shop, Xtrace.app, in collaboration with Inspiron Systems, implemented an advanced shop system featuring Balances Marques scales, recognized for their excellence in the weighing industry. This integration allowed for seamless retail label scanning into the Marques EPOS system and precise weighing of meat from the factory to the shop. Furthermore, the Wyre Pie Company's preference for MAC systems was seamlessly accommodated by Xtrace.app, highlighting its versatility and essential role in their business operations.

A NEW HARVEST

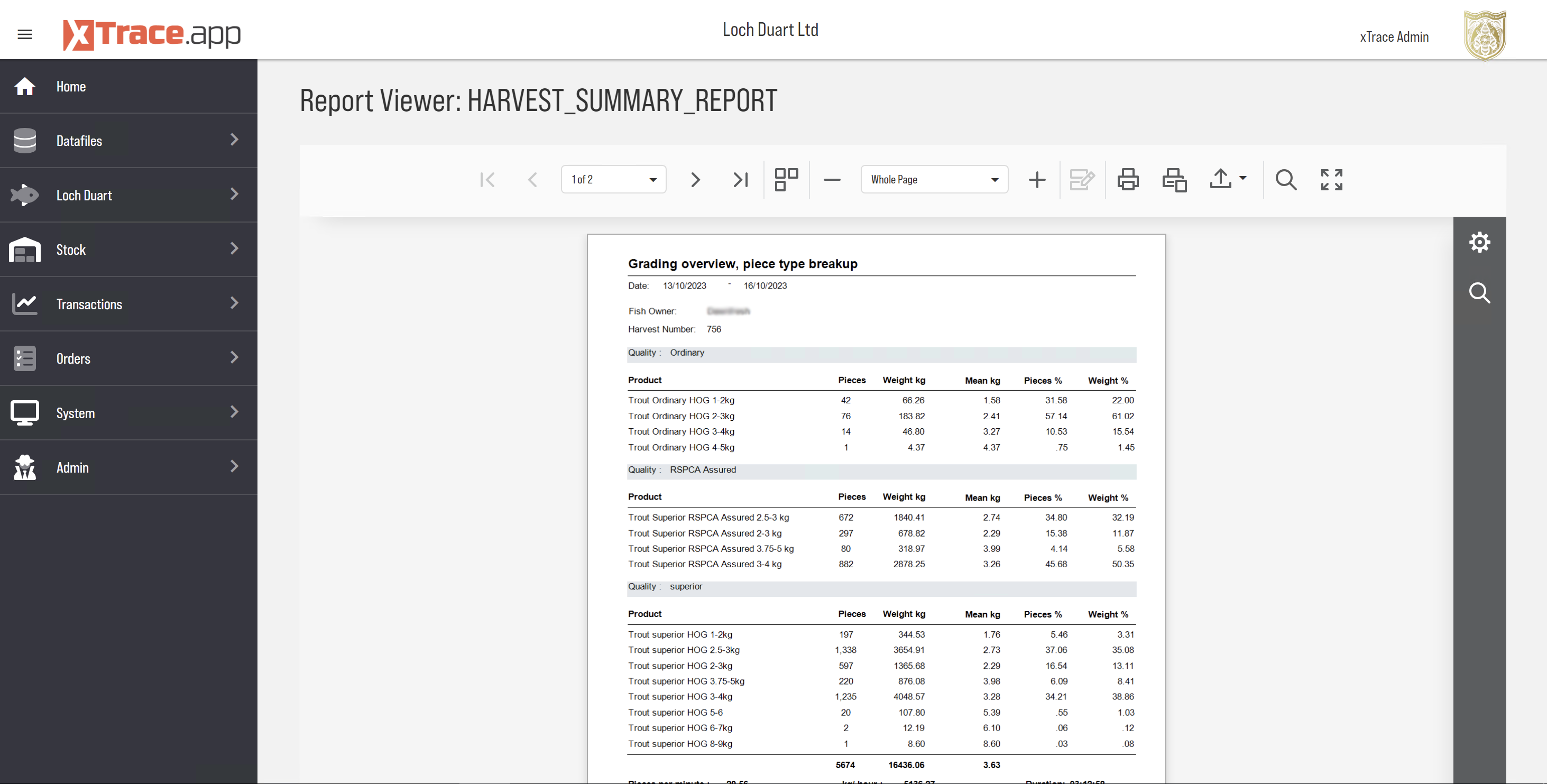

While working on the Wyre Pie Company project, Xtrace Systems simultaneously undertook an upgrade for Loch Duart Ltd, a salmon packing company in Dingwall, Scotland. This upgrade involved integrating their existing Microsoft SQL server database with the new Xtrace database. The transition was smooth due to the compatibility of the database systems, but the significant change was in the integration approach. Xtrace.app moved away from the highly integrated structure of the previous system and instead utilized its own database, interfacing with third-party systems via APIs. This method proved to be more efficient and platform-independent.

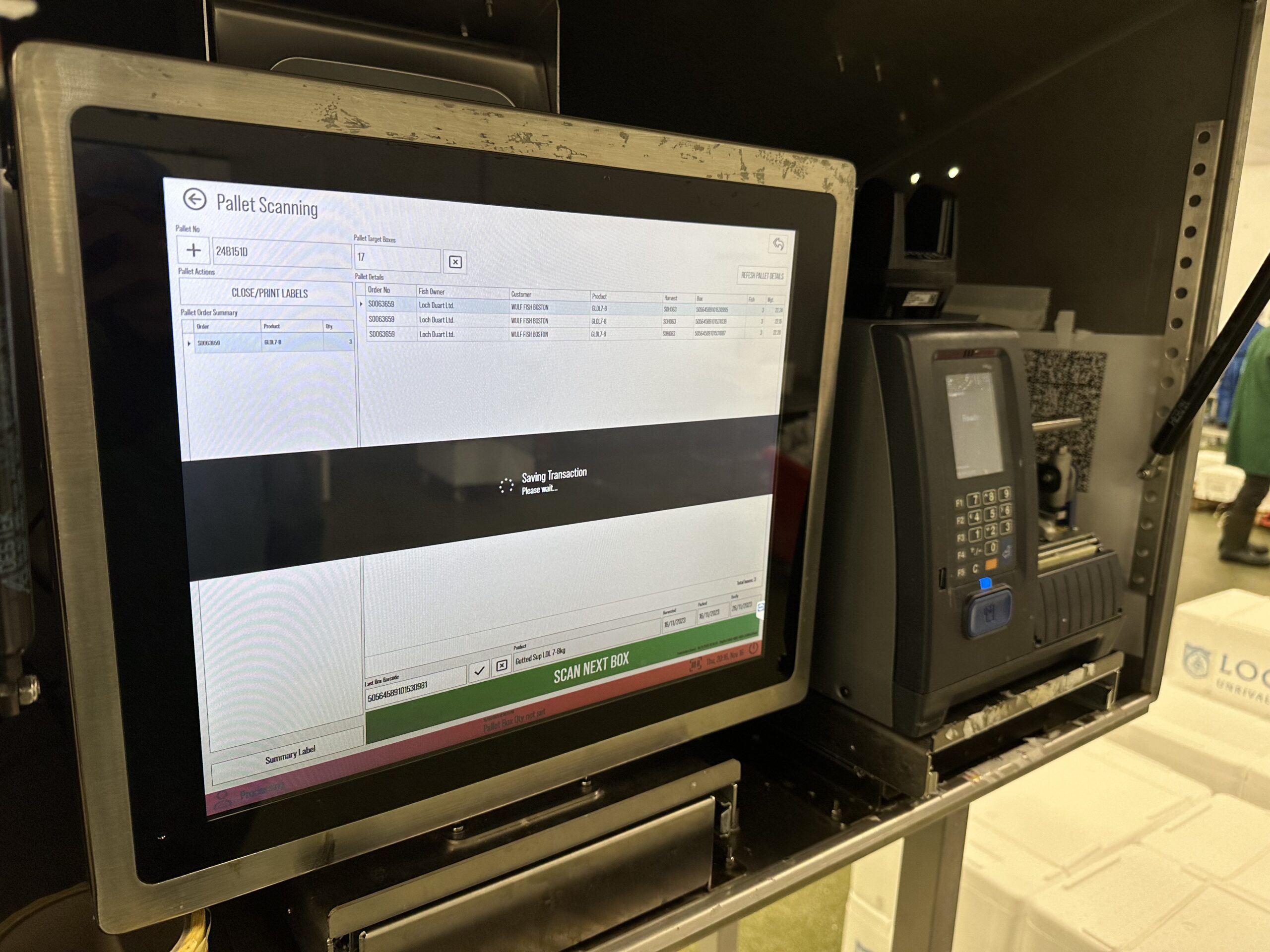

Loch Duart quickly adopted Xtrace.app, starting with the harvest Production Summary report, developed using the Xtrace.app report writer and generator. This feature has now become a key component of the Xtrace.app web client software. Furthermore, Xtrace Systems recently introduced the first Xtrace shop floor system (Xtrace.touch) at Loch Duart. This system allows for the scanning of palletized boxes, generating pallet summary labels and detailed palletizing reports, significantly improving the efficiency and precision of their operations.